Graphic: copyright CO2CRC

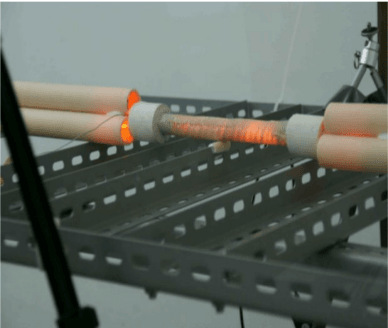

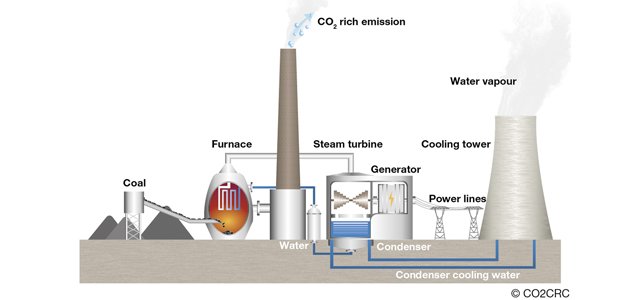

Because the grade of heat generated [and recoverable] from the cold fusion processes [as of now] is modest in relation to furnace temperatures of conventional power plant [ which are in the range of 2500- 3500 deg.F (1400C-1900C)], it is not obvious to me how the existing furnace/ boiler plant can be efficiently utilized for the cold fusion processes.

However, if the CF energy cell is used directly to generate saturated steam at pressures in the range of 500-3000 psig. (pounds per square inch gauge) where boiling temperatures would be in the range of 470-700 deg.F (240C-370C) [respectively for the pressure range] and then, a separate CF energy cell is used to directly superheat that steam to 750 deg.F (400C) for a 500 psig. and to say 1000 deg.F (540C) for the 3000 psig. boiler, then that superheated steam [for what ever steam pressure system is used] could be routed to an existing steam turbine plant [with the return treated and de-aerated condensate returned as feed to the new CF fired boiler.

In summary, the existing fossil-fired boiler plant [including all fuel/ combustion air/ furnace/boiler/ash systems/flue gas systems, are all deactivated and preferably removed, and the new cold fusion powered boiler together with the cold fusion powered superheater would be integrated into the existing steam turbine generating plant [including the steam condensing plant and, of course, a modified control room].

This whole project would certainly drastically reduce emmissions to zero, but would be very costly, I suspect, because of labour costs of dismantling the majority of the power station.

It may be a better option to build new power station using the new CF boiler and superheater plant with a custom designed and compact steam turbine/ generator plant in a small modern compact building.

With the most appropriate and efficient small 25MW cold fusion powered station I would suggest the following :

Boiler outlet conditions : 500 psig. sat. steam [at 470 deg. F (240C)]

Superheater outlet conditions : 470 psig. steam at 750 deg. F (400C)

Steam Turbine outlet conditions [to steam condenser] : 1 psia. @ 10% wetness.

The practical steamrate for generating electrical power with this relatively simple, small and compact station is about 9 lbs/ kwhour so the total steamrate from the small boilers serving a single multi-stage steam turbine/generator system which exhausts to a steam condenser is 225,000 lbs/hour.

Scientists would decide how much steam capacity each boiler/superheater combo would have and that would determine how many units would be required to meet the total steam demand.

Note: The use of steam for electric power generation [via boiler and steam turbine as presently done] is really 20th. century technology and all forms of cold and hot fusion should seek to find DIRECT electrical generation processes that harness ion transfer in conjunction with an external excitation field.

The use of steam at high pressure as an electrolyte, may however make use of an abundant commodity that facilitates extreme process efficiency, and this applies to the pressurized CIHT unit where high pressure steam is extremely efficient as an electrical conductor [the electrolyte] permeating the catalyst fill [consisting of back to back catalyst discs] through micro gaps in the catalyst structure. Further the basis of direct electric power is when a stream of ions or electrons flowing and driven by an existing voltage potential, will interact with an external excitation field thus creating export electric power.

Addendum:

This proposed and detailed [perhaps speculative] bold upgrade to the original BLP – CIHT unit could be a blockbuster in that a compact direct energy CIHT based system, offered in a wide range of sizes and used in multi-module applications for the power generation industry, but more importantly, for the shipping industries [from private and recreational craft to commercial shipping and naval shipping including surface vessels and submarines].

This conceptual unit [or units] could be installed in the ships engine room and bypass the existing electric generating plant with out the costly removal of that plant [or in the case of nuclear powered vessels deactivate and bypass the entire systems of the existing reactor compartment].

See details on The PRESSURIZED CIHT Unit [.pdf]