Open Power Association Newsletter #14 has been released. The newsletter is archived in Italian here. The following are a few google-translated and slightly modified excerpts that refer to cold fusion-related activities.

From 22 to 28 September was held in Rhodes (Greece) International Conference 2014 on Numerical Analysis and Applied Mathematics. Ugo Abundo was invited to participate in the proceedings as a representative of Open Power, to discuss the results of the activities that are part of the Association.

The work has been focused on the re-establishment of new mathematical foundations of physics, able to address the many issues currently unresolved, through change of paradigms in force. The new isomatematica (and evolutions “geno” and “hyper”) Professor Ruggero Maria Santilli presented as the appropriate tools to deal with maps deformed intrinsic irreversibility fields to ipervalori.

By means of these tools, it has been shown by speakers from all over the world, in view of industrial development, advanced applications in the field of energy, and in particular, in regards to the structure of the neutron and the atomic behavior for the purpose of nuclear synthesis. In the previous treatment of such areas, the math, as well as Quantum Mechanics appears inadequate. Hadronic mechanics, specifically developed by Prof. Santilli as an evolution of the above when both distances between particles comparable to the size of the nuclei, is revealed adequate to treat nuclear-type energy situations, where the particles can not be assimilated to material points, as in Quantum Mechanics.

Ugo Abundo presented in two separate reports, the LENR experiments conducted in the Open Power laboratory, and a neural network model generalized setting from the field of Artificial Intelligence, which makes homogeneous Quantum Mechanics and the Hadronic, justifying the applicability conditions of each of them, showing from the mathematical point of view, what happens in terms of internal information to physical systems when the first turns in the second.

Abundo’s report, entitled “An intrinsically Irreversible, Neural-network-like Approach to the Schrödinger Equation and some Results of Application to Drive Nuclear Synthesis Research Work” [.pdf] has been accepted for publication as part of the American Institute of Physics in the Proceedings of the Conference. Hence, the conditions for collaboration with other mathematicians (mainly French, Indian, Greek) to jointly pursue such studies about the applications of AI in the field isomatematica and subsequent transferability to modeling of elementary particles in interaction.

Ugo Abundo presentation slides http://www.hydrobetatron.org/files/ABUNDOpdf.pdf

It is certainly easy to understand and explain briefly the complex thought articulated by Prof. Ruggero Maria Santilli, developed in the ‘arc of 40 years of work, both theoretical and experimental. Remarkable also is the amount of writings, conference papers, and scientific publications, he authored. This website has as main purpose to spread all those materials, video lectures, writings, etc.. In which Santilli describes in clear words and straightforward His theories and their mathematical models; His experimental paths (and industrial), and insights for the future of scientific research and experimentation in the field of new energy …

Here lists the work and thought of Santilli, who (unlike many academics pigtails Italian or not), does not miss at all courage in an attempt to place in certain areas more correct and the same theories of Eintein (Holy Grail?), and even quantum mechanics, from certain points of view. He did not even hesitate to take a picture of the “Science Today”; a photograph very brave, uncomfortable, and merciless; in substance, very critical …

In fact, he argues more explicitly that “the greatest responsibility for the crisis of physics should be seen in the press as a result of the total subservience to the centers of scientific power, while the political responsibility is only indirectly, as the political world uses print as a medium of information and action.”

This website has been designed so as a sort of very concise and articulate “compendium”, the enormous scientific thought and work Santilliano not yet sufficiently known and disclosed, and therefore unappreciated by the general public (at least in Italy, in my opinion), but certainly well-known and much appreciated from a small circle of experts and professionals, even in Italy, for his innovative value; a “compendium” I said for the use of those Italian researchers thirsty and with the critical spirit of true knowledge, but alas mè, with little time available to study the large amount of material and information that the Internet provides us every day.

Prof. Ruggero Maria Santilli Works and Thought http://www.nuovascienza.org/

Third-party report on ‘E-CAT released — Andrea Rossi

Observation of abundant heat production from a reactor device of and isotopic changes in the fuel [.pdf]

Giuseppe Levi

Bologna University, Bologna, Italy

Evelyn Foschi

Bologna, Italy

Bo Höistad, Roland Pettersson and Lars Tegnér

Uppsala University, Uppsala, Sweden

They Essén

Royal Institute of Technology, Stockholm, Sweden

ABSTRACT

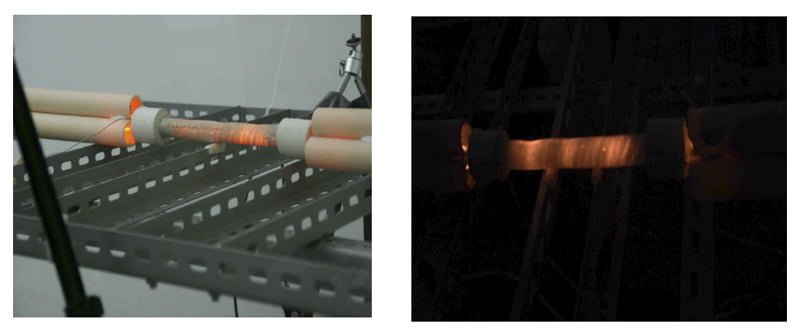

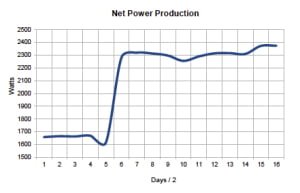

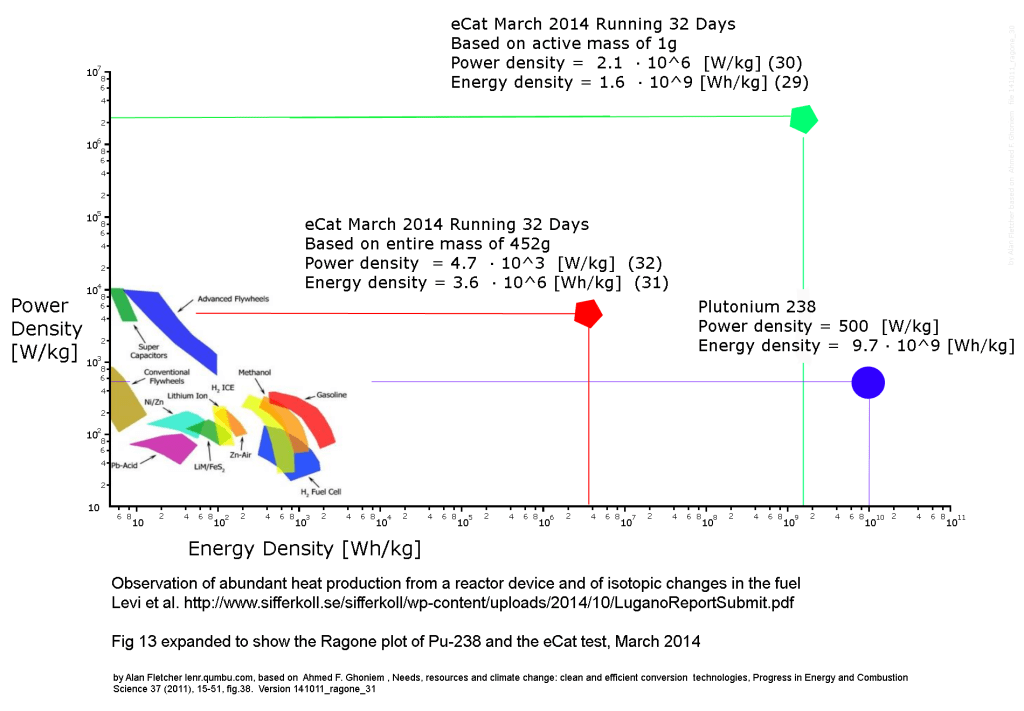

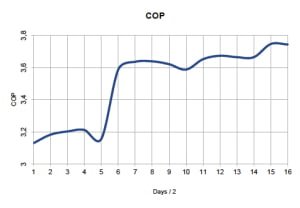

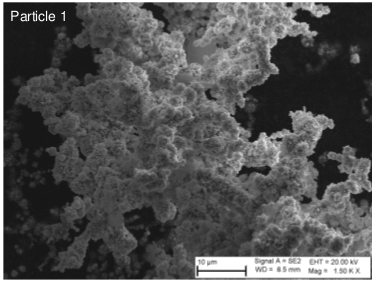

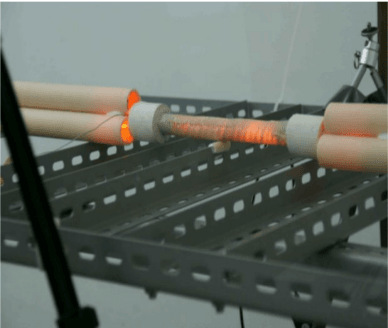

New results are presented from an extended experimental investigation of anomalous heat production in a special type of reactor tube operating at high temperatures. The reactor, named E-Cat, is charged with a small amount of hydrogen-loaded nickel powder plus some additives, mainly Lithium. The reaction is primarily initiated by heat from resistor coils around the reactor tube. Measurements of the radiated power from the reactor were performed with high-resolution thermal imaging cameras. The measurements of electrical power input were performed with a large bandwidth three-phase power analyzer. Data were collected during 32 days of running in March 2014. The reactor operating point was set to about 1260 ºC in the first half of the run, and at about 1400 °C in the second half. The measured energy balance between input and output heat yielded a COP factor of about 3.2 and 3.6 for the 1260 ºC and 1400 ºC runs, respectively. The total net energy obtained during the 32 days run was about 1.5 MWh. This amount of energy is far more than can be obtained from any known chemical sources in the small reactor volume.

A sample of the fuel was carefully examined with respect to its isotopic composition before the run and after the run, using several standard methods: XPS, EDS, SIMS, ICP-MS and ICP-AES. The isotope composition in Lithium and Nickel was found to agree with the natural composition before the run, while after the run it was found to have changed substantially. Nuclear reactions are therefore indicated to be present in the run process, which however is hard to reconcile with the fact that no radioactivity was detected outside the reactor during the run.

Read the full report: http://www.hydrobetatron.org/files/ROSSI.pdf

Newsletter compiled by L.S. and the Open Power Association