Press Release from Ecat Australia and Ecat South Asia – August 2013

TOMORROWS ENERGY, TODAY

Since we last wrote, there continues to be important developments. The rest of the world is waking up that L.E.N.R. is serious. A recent Forbes article emphasized the maturing of the technology.

And OilPrice.com journalist Brian Westenhaus thinks the industry may have reached the turning point and perhaps the last stages before widespread acceptance. This is further supported by an influx of universities in the US and afield that are now including LENR or Cold Fusion studies in their syllabus.

The 18th International Conference on Cold Fusion (ICCF-18) held last month also provided substantial details of the technology along with deepening understanding of the physics behind it. In practice no-one is yet able to match the COP that Rossi has attained: COP=6, but we hope that all parties do succeed because there is much need for more efficient and environmentally friendly energy sources.

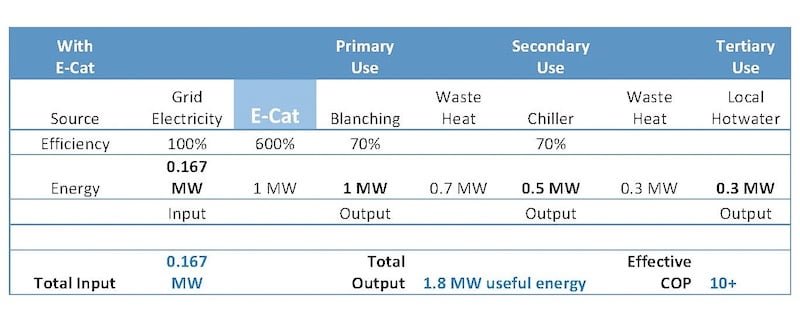

Our focus has continued to be on working with interested parties, discussing their needs and recommending solutions. The following diagram shows the wide applicability of the Rossi E-Cat and Hot-Cat.

Many companies around the globe and in this region are starting to focus on co- and tri- generation, the situation where one heat source is used over and over again. To this end the actual effective COP can be much higher than 6, if one can re-use the heat. A typical co-generation use could be using the initial heat for a food manufacturing process, and the waste heat for a chilling/refrigeration process.

Consider a typical Co-Generation opportunity: Fruit and Veges industry.

Primary Application: Blanching. For this, typically they would be using grid electricity, or Gas. With the E-Cat they would enjoy a COP of 6 (i.e. for every unit of energy previously used, now they can consume just 1/6th of that energy, reducing their bill proportionately). Once used the energy they have consumed is typically wasted.

Secondary Application: By coupling the blanching process and its waste heat, to a chiller system, the company can convert this waste heat into chilling, allowing operation of cold rooms for holding vegetables, at almost no additional energy cost. Assuming a 70% efficiency on this leg, the company might be able to get an additional 50% re-use of the energy (allowing for inefficiencies).

Now the company may also consider that there is a third use for the same energy – output from the Chiller is hot water (approximately 50-70 degrees C). This is ideal for general use in bathrooms and kitchens for washing and cleaning.

Notice from the example table above, that there is substantial improvement of the facility’s energy use. Using the E-Cat, the company may be able to achieve upwards of 10 times the value of the input energy. (note this is a generalized example. Engineers will be able to estimate specific applications which depend on environmental conditions and other factors).

E-Cat Australia and South Asia is working with manufacturers and distributors of allied equipment to assist our clients get additional benefit when they implement an E-Cat or Hot-Cat.

E-Cat Australia and South Asia is working with manufacturers and distributors of allied equipment to assist our clients get additional benefit when they implement an E-Cat or Hot-Cat.

Regards

Roy Wise, B.Chem.E, MBA

www.EcatSouthAsia.com

and Roger Green

www.E-catAustralia.com

Related Links

Live Stream of E-cat Conference in Zurich September 7, 2012

E-Cat Australia launches new website July 16, 2012

Obviously, the gold standard of energy is in the form of electricity. It is too bad that the above chart shows that “high temperature steam turbines” can’t even be powered with the high temperature of the E-Cat HT. I suppose they are instead going to get the low hanging fruit of just about every other heat generation business application.

If anyone in the know is reading this, there have been rumors floating around that LENR may be able to be used for electricity generation without resorting to the Carnot process. May be a pipe dream, and instead we’ll have to go the Sterling turbine route eventually instead.

Frankly, I was really hoping that LENR could be used in existing power plants to supplant either coal, natural gas, or nuclear. Instead, it is beginning to look like those will be around for a while longer (with perhaps LENR “pre-heating” the water so fossil fuels or nuclear fission need only be used to heat it the rest of the way to dry steam). 🙁

Hello Brad:

There’s no such a device as a Stirling turbine. There is a Stirling reciprocating engine, and, as we know, a good reciprocating steam engine, like the Pritchard (Australia), Vapor , or Cyclone (U.S.) machines can run very well on ordinary low pressure/low temperature steam as happened with the agricultural and industrial steam engines of yore.

Not sure where you see the limitations. It is like saying that the Model T Ford will hold the world land speed record until 2014. That didn’t happen. ECAT to HOT CAT to Super Hot Cat?