Here is a link for a Live Stream of the E-Cat-Hot Honeycomb Zurich conference taking place — (EDIT) September 8-9. (sorry, original post had Sept.7th)

http://www.ecat-deutschland.org/index.php/live-stream

Here’s a program pdf of the entire conference breakdown, schedule, etc. in English –

http://www.borderlands.de/Links/Kongress080912M-e.pdf

Live streaming is here from UStream:

http://www.ustream.tv/channel/z%C3%BCrich-09-2012-live

Here’s the recorded video that was posted from Day 1, with many thanks to steverybak:

E-cat World has published three associated files about the Hot Cat for this event.

Hot Cat Corrections Powerpoint

This file documents a test of the Hot Cat by Fabio Penon and David Bianchini: Penon4-1

Some points from Andrea Rossi’s talk on Day 1 are listed. (The list is not comprehensive due to loss of stream):

- The E-cat Congress was organized in part by Adolf and Inge Schneider from TransAltec Inc. in Zurich, Switzerland.

- Andrea Rossi spoke in the evening and announced that the industrial version of the E-cat has been certified from SGS, limited to the safety features. SGS is a company that provides inspections, testing, certification and training for scientific research and consumer products.

- The 10 kilowatt consumer steam generator has been more difficult to certify due to the safety considerations when utilizing a hydrogen tank.

- The new Hot Cat reactor can withstand up to 1200 Celsius degrees and a special paint was invented specifically for use in the E-cat. Internal temperature can reach 1250 Celsius degrees while external surface can reach 1050 C.

- Inner core has dimensions length 33 cm, outer diameter 9 cm, inner diameter 3 cm made of AISI 310 steel to withstand higher temperatures.

- David Bianchini, a physicist from the University of Bologna made radiation measurements outside of the reactor that was crucial to the certification. Rossi has said he has been “just a spectator” during those measurements.

These measurements are extremely important because of safety, “no radiations should go outside the reactor” says Rossi. Bianchini’s report concludes there is no significant radiation above background, summarized here:

-

- One charge of hydrogen fuel is 1 gram for six months of 10 kilowatt power continual operation.

- A prototype Hot Cat generator appears to have a minimum COP of 2.5. Planned commercial product has COP of 6.

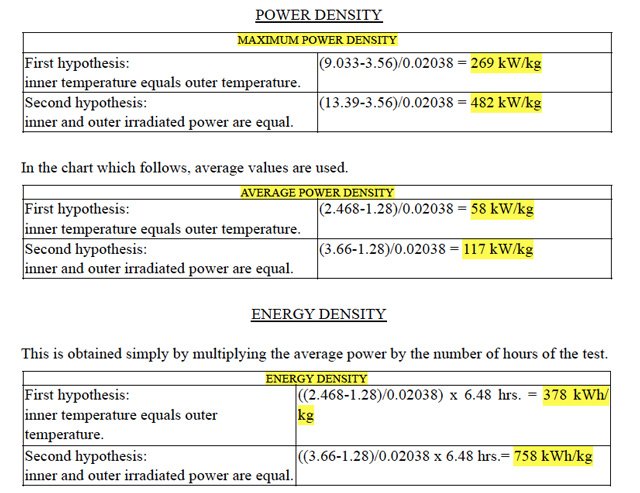

- Energy density measured and calculated by Penon resulted in these values:

- A full report on Hot Cat specifications will be released in two months time after repeated tests of a similar nature.

Day 2 of Ecat Conference had a number of panels. Recorded video posted follows:

Here is a partial transcription of Roger Green’s presentation panel:

Use Ecat to make ethanol, says Roger Green. “Food is for people.”

Green of E-cat Australia and Eco Global Fuels describes the hydroxy method, which takes seawater to make ethanol, and how Ecat can power the process.

“Industrial heat is a commodity to start with. We’re talking about developing it down the line for desalination and transportation.”

“It’s no longer research and development”, Green says of the applications for the Ecat technology. “It’s actually a scale-up.”

“When you run the hydroxy generators, you have iron as a by-product. We know exactly how much, and the iron goes into creating algae. We decided to use a bit of the excess energy to make bio-char.”

“I love solar, but it’s expensive. With the Ecat“, Green says, “we can sequester CO2 and make a renewable fuel.”

William Donavan [contact] who has been investigating various free energy systems and providing consulting services for energy and propulsion for years, is Green’s Chief Technical Advisor. He described how the Ecat can assist in desalination for clean water.

Conventional desalination is energy intensive and requires huge boilers. “The biggest problem is the heat of vaporization and the heat loss to the environment.” Reverse osmosis wastes huge amounts of water, despite being the most popular method of desalination.

“Low-pressure distillation currently uses petroleum to run generators that run 24-7. This is potentially an application for LENR.”

Donavan listed a number of desalination methods with their pros and cons. Energy and Environmental Science issue #10 highlights Capacitive Desalination, which is on the horizon, and researchers at MIT are working on Graphene Desalination.

“Though the global recession has put a dent into the contracted capacity, demand is still outstripping what can be done now.”

He cites statistics from Global Water Intelligence that, in 2012, “the global desal market will add 6.4 million cubic meters per day (1,690 Million Gallons per Day) of capacity valued at $9 billion,” including both “brackish and seawater desal”, and “equipment sales could surpass $18 billion by 2016”.

“They’ve got the equipment; what they haven’t got is the energy to do it, which I think, we can supply that for them,” said Donavan.

The oil industry is also looking for water recycling for fracking operations. They are contaminating the aquifers, and this requires remediation.

The Ecat technology offers a solution for clean-up.

“There are literally millions of square kilometers that are contaminated, and the aquifers are no longer useful.” LENR is “a good fit” to solve these problems, and being green, “it’s acceptable to the environmental community.”

And for business interests, Donavan says, “billions are to made in global profits.”

Sitting in the audience was Andrea Rossi, who had previously considered desalination as an application of Ecat technology himself, but turned away from it due to the cost-effectiveness compared to osmosis, was impressed with Donovan’s ideas. “This is a dramatic game-changer”, he said of the newer technologies.

Rossi asked, “Have you made a comparative economic analysis between the cost of desalination of water made with the Ecat and made with reverse osmosis?”

In answering, Donavan cited “Waste to water: a low-energy water distillation method” [.pdf], a study by Florida Atlantic University researchers led by Brandon Moore, along with two other studies done by and Israeli group and a Russian group, where the average consensus was, “a 40% reduction in energy” use with the Ecat over osmosis, though Roger Green admitted they are still getting benchmarks in the R&D program and “don’t have it down to that number yet – that’s what’s possible.”

Moving into the “heat to electricity” portion of the talk, Donavan began by stating that “Conventional turbine to hydrogen, and then to electricity, is the worst efficiency of all.”

“24% efficiency power generation into 20% efficiency electrolysis yields an overall efficiency of 4.8%”, using a conventional turbine, with “95.2% of heat wasted”.

“Though politically correct, the so-called ‘hydrogen economy’ is uneconomical and environmentally disastrous.”

“Only on-site generation is practical.”

Now a conventional turbine has a 30% efficiency, and with an 80% efficient alternator, the combined efficiency yield is only 24%, leaving 76% of the heat wasted.

This type of system is only feasible when you can use that wasted heat. But this is how conventional power plants operate – using the wasted heat as “environmental heaters”, i.e. heating the environment.

A Tesla turbine has a high efficiency, from 50-80%. Using the lowest efficiency with an 80% efficiency alternator yields an overall efficiency for electrical power of 40%.

This mature technology was proven in 1911!

Thermoelectrics is another robust technology to provide electrical power generation known since the 1950s that provides a comparable efficiency to photovoltaic electricity generation, costing $10 per watt with 200 Watt units costing $1919.00.

Devices available now [visit] are solid state with no parts to wear out, can work by convection, and can be used for co-generation with temperature over 270 degrees Celsius are typical.

These units are highly adaptable to LENR though not as price competitive as the turbine and alternator combination. Thermoelectric generators have been used on for spacecraft power for decades, but the true life expectancy of these devices have yet to be determined. They also need an inverter to turn output into AC as well as high-temperatures to operate, around 1226-1726 degrees Celsius.

Stirling engines, originally designed by Robert Stirling in 1816, can reach efficiencies of 50% if configured correctly, and gas can be looped through a LENR reactor as a primary method of cooling.

On the downside, these types of engines need higher temperatures to be more efficient, between 500-1000 degrees Celsius and the high pressures are more difficult to “seal in” over time. It also has more moving parts than other methods of converting heat to electricity.

Variants of the Stirling engine include the free piston engine design, of which Siemens uses the Alpha (three to six cylinder) version, the Beta configuration, a high-output and stable version, and a new 10-year-old technology called a Quasiturbine Stirling, which may hold the most promise teamed up with LENR.

Research at the NASA Glenn Research Center is being done on a Stirling Radioisotope generator which puts out 12.5 kilowatts per cylinder, a close match for the 10 kilowatt output of the small Ecat.

There are Rotary Stirling system, some of which are even more efficient than the other alpha, beta, or gamma, Stirling designs. This technology was abandoned to pursue “cheaper” engines, but is “begging to be repurposed for LENR.”

Stirling Engine Forum http://www.stirlingengineforum.com/

For converting heat to electricity, there are several horizon technologies. One is Quantum Well technology. Operating at a relatively low 450 degree Celsius temperature differential, they can run as high as 800 degrees, providing efficiencies as high as 32.5%, and higher in the future. Future efficiency if 50% or more then compete with turboelectric conversion systems.

These high efficiencies utilize capton substrates, as well as other engineered plastics, act as a “heat funnel”.

This technology is being used by military on Abrams tanks as a 5 kW energy conversion system, and we need civilian use!

Efficiencies as high as 92% come from experimental IR (Nano) Antennas, where infrared radiation is directly converted to electricity. First proposed by Steve Elzwick in the 1980s, the development was stymied by the lack of teraherz diodes not fast enough to operate, but they are on the market now, which makes this thermoelectric technology “begging to be developed.”

Applications being researched at the Idaho National Laboratory include solar cells that work at night.

Interestingly, you can cut these types of nanoantennas to 1/4 wavelength of your blackbody temperature. This means that when the infrared radiation (heat) approaches that temperature, the nanoantennas begins to converge and acts like a self-regulating thermostat.

Wrapping up his talk, Donavan listed a number of applications for LENR technology: adsorption type refrigeration and HVAC systems, hybrid cars and trucks, substitutes for diesel-electric locomotives, turbine-driven ships and submarines, replacements for spacecraft power currently using radiothermalisotope generators (RTG), exotic propulsion systems for space planes, and locally-generated power not connected to a grid.

Many of these applications have already been proposed and are actively being pursued. For instance, the Navy is interested in replacing their reactors on their nuclear submarines.

In conclusion, while almost all thermoelectric conversion technologies have merit, when nanoantennas are available, that one will be the most efficient.

Bot Stirling and Tesla turbines are close competitors in cost as well as efficiency to mechanical power conversion, but the only ones that do NOT measure up are the conventional power conversion systems in use now.

Roger Green closed the talk with a business proposal for their R&D efforts at e-Cat Australia. Their research efforts are based in labs located in the south of France and Sydney, Australia. The talk left out two or three proprietary products-in-development.

The company is focusing on two products in particular, a small prototype for the low-pressure desalination unit, as well as the most innovative heat-to-electricity technology, and they are looking for only about $200-300 thousand to do it.

Sourced from global search for talent, Green is thrilled to have William Donavan leading the R&D.