Frank Acland started E-CatWorld.com on April 4 in the year 2011 after Andrea Rossi had performed a public demonstration of his nickel-hydrogen-based steam generator named the Energy Catalyzer, or E-Cat.

“A Focardi-Rossi news conference was late in January of that year, and I became aware of it through some friends. I just got interested in it, and thought, why isn’t this being reported on more anywhere else?” he says.

“I thought it was a story worth following, and I thought it was worth putting out there, and once I started, I really haven’t been able to stop.”

Listen to Frank Acland on the Cold Fusion Now! podcast with Ruby Carat on our podcast page.

“To me, the story has never died. It’s become a long and winding road, but I’m just as interested now as I was then. So I haven’t stopped, and I don’t plan on stopping until there is some obvious resolution. Since I don’t know what the future holds, I’m just going to keep going until something happens where I can’t go any longer.”

Back in 2011, the Vortex-l mailing list was where speculative science and new energy talk happened. ColdFusionNow.org had been in existence barely a year, and rejected the belicose comments and unknowable claims. E-CatWorld.com stepped in to host the debate over Andrea Rossi’s technology, but even there, comments were quickly curbed to prevent all but the news and blow-by-blow of the engineering developments.

“I didn’t want to be administering a website that was full of acrimony and arguments, so I set up the rules that I was comfortable living with,” says Frank Acland, whose been actively screening the comments since.

“I wanted E-Cat World to be a place there this topic is taken seriously. I have always felt that Andrea Rossi came up with something important. I’ve never felt he’s been telling a big lie all years over what he’s done, though, obviously, he’s extremely secretive. So I just made it a policy that this would be a forum where we’re not going to argue over whether he’s a fraud or liar – that’s not what I wanted the website to be. I’ve set up moderation rules that are listed on my site and I’ve stuck to them.”

“I know there’s some people who don’t like the fact that certain comments are not allowed on the site. People can talk however they want to elsewhere. For me, it’s worked well.”

With over 3000 posts to-date, E-CatWorld maintains a hopeful outlook on a Rossi reactor. Frank Acland is not a scientist, but a librarian by training, and has catalogued the details of the E-Cat drama since it emerged through the Internet in 2011.

A visit with Andrea Rossi

It was 2017 when Frank Acland visited Andrea Rossi. “I received an invitation to come and visit with him in Florida in March, early 2017. He took me to his lab, and I believe it was in the actual Doral facility where he had been running that big machine for the yearlong period.”

“I never actually saw that unit. This was right in the middle of the lawsuit with Industrial Heat. He spent the year inside the shipping container, and this was shortly following the end of that test and when he was involved in litigation.”

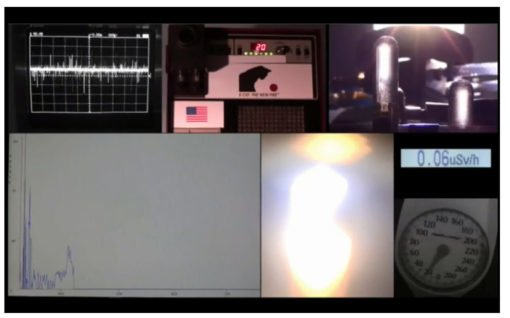

“At that point, he was working on the Quark, it was a small machine that was on the desktop. The best picture of that has been published by Mats Lewan back in January. It was a little tabletop thing. We took measurements and he showed me calculations, and at that time, the COP was around 20,000 or something like that. That was at the beginning of when he had developed the first iteration of the plasma system, and that’s what he’s continuing to work on now.”

See QuarkX presentation and Mats Lewan’s presentation .pdf Nov 24, 2017.

E-Cat QX Claims: volume ≈ 1 cm3, thermal output 10-30 W, negligible input control power, internal temperature > 2,600° C, no radiation above background.

“It was fascinating of course, because I’d never seen an E-Cat in my life. I was a student and he was a tutor. He was showing me what he had, he was taking measurements with a spectrometer. He showed me how he calculates the energy in the plasma. Of course, this is not an area where I have any expertise at all. I was basically sitting there like he was the teacher and I was the student, and he was explaining how he was coming to his conclusions as to what the COP was.”

“So I saw it with my own eyes and I kind of followed along with his calculations. But this was in the early days, and I did notice there was a big control system on the desk, and he was putting some kind of secret waveform into his plasma, and I did not know what was in there.”

“He was measuring the energy on the plasma side of the control system, but he wasn’t measuring the input into the control system. So there was that issue.”

“I was basically there as someone who was following along, and thinking, ‘Wow, if this is true, it’s a really a very big deal.'”

“At the time that I went, before I went into the room, he pulled out a piece of paper and I signed an NDA. While I was there, I wasn’t taking photographs. I realized that this isn’t something I’m going to be able to go home and report about.”

“Later on that year was the presentation held in Stockholm, and he showed the same system, and then I asked him after that, OK now you’ve shown to to the world, is it OK if I report on what I witnessed? Basically, what I saw was what he showed in Stockholm.”

Videographer Eli Elliott and Andrea Rossi are seen in Miami, FL when Cold Fusion Now! visited and interviewed Andrea Rossi in 2012. Polaroid Photo: Ruby Carat

The MegaWatt IH Lawsuit

Frank Acland had visited the Doral location, but had never seen the MegaWatt unit. Andrea Rossi had abandoned the idea of a large energy generator and returned to the problem of controlling the reaction in a smaller reactor first.

Says Frank Acland, “I never saw the megawatt unit. All I learned about the megawatt unit is what he reported during that time, and what came out in the court case.”

“I think the megawatt unit actually worked, but it sounded like he had to be there constantly to keep it going, it needed constant care and attention. It was not something he could commercialize in that at that point in that format, but I believe he learned a lot from it.”

“I think he was able to translate information he got from the big unit and start making small units, and he’s still perfecting it, so we’re not there yet.”

Why did Andrea Rossi give up on the possibility of $100 million dollars and support to develop the reactor offered by Industrial Heat? Frank Acland gave his take.

“I don’t much beyond what was reported in his blog and also what came out in court, but when Andrea Rossi made a deal with Industrial Heat, my sense is he probably thought they were going to be supporters of him, and that they would be working together. When they started working with other researchers – and I think this was the thing that upset him initially – was that they were not only supporting him and the E-Cat, but they were supporting other researchers.”

“I don’t think that sat well with him. As we know, from the very beginnings, he’s very circumspect about what he says about his technology. He probably told Industrial Heat things that he assumed were going to his supporters – and this was one of the complaints in the court case – that he was concerned that they were sharing things that he told them in confidence with other researchers. Maybe he felt like his IP was being violated or shared, and that was not what he was hoping for when the deal was initially struck.”

“That was not something that he had envisioned, and he wanted to fight to get out of it. I don’t remember the day when he started that lawsuit, but that’s when everything blew up.”

See Rossi v. Darden docket and case files here courtesy ColdFusionCommunity.net.

Frank Acland is still confident in Andrea Rossi’s ability to generate a reaction, but whether or not a technology will emerge from the Leonardo Corp. lab is another question.

Andrea Rossi stays the course

“My feeling is that yes, I think he has a very advanced technology. That may not be the consensus. I think a lot of people had hoped that following the press conference with Sergio Focardi, all of this would be out in the open by now, and we’d be using E-Cats in the business world, if not in our homes, but it’s been a long time.”

“But my impression is that Andrea Rossi has always had very big ambitions as an industrialist. As an industrialist, he is extremely secretive because probably – and I think he’s a very smart man whose worked extremely hard over these years – but, if somebody knew what they were doing, and knew the ins and outs of the E-Cat it would not be too difficult for them to replicate, and I think that’s something he definitely does not want to happen, because as an industrialist, this is not in his business interest to share this information.”

“I think that’s the reason he is being so guarded. He wants to make that possibility as slim as possible. I don’t know if that’s possible to happen. There are many people who realize there is something this LENR phenomenon, and mainstream science has dismissed this as being an area for people on the fringes of science.”

“When the day comes that they realize, ‘hey this is for real’, I think there will be an explosion in research and there will be people developing this technology in different ways all over the world, and at that point, it will be impossible to keep secrets.”

“But I don’t think Andrea Rossi is going to change his course. He’s made the decision on how he’s going to go about it and I think he’s going to stick to his guns.”

When asked if Andrea Rossi has heard about the Tadahiko Mizuno report, Frank Acland said “His standard response when it comes to questions like that is, ‘I never comment on my competitors.'”

“I don’t know what he thinks about the Mizuno report. Obviously, if they are using systems that he has experience with, then I’m sure he’s paying attention to it, and trying to maintain his advantage.”

“I think he might be able to learn from people, but I don’t think he’s going to collaborate with people. That’s just the way he’s operated all these years. I’m sure that he reads; I’m sure he pays close attention to what gets published. I don’t think he’s going to change his way of operating. He’s set his course and he’s going to do his best to stick to his course, and whether it’s successful or not , we’ll have to see.”

“I honestly think he has a very advanced technology. I do not know how successful his business plan will turn out to be. That’s yet to be seen. It’s still not entered the mainstream of business or industry. As he said recently, ‘he is in a pioneer phase’. So I think he’s working with select customers. I have no information about who any of his current customers are. There’s a great deal of mystery, even to me, though I’ve been following it closely for years.”

“I’m not really scouring the Internet – ‘oh, who could he be working with?’ Unless someone reveals themselves, I don’t think we’ll know. Until there is something to sell or on the market, it will take a customer speaking out to get more information.”

Optimism fuels the future

Several other labs have recently achieved increasing levels of excess heat from their heat generator designs, including Tadahiko Mizuno, who has reported kilowatt-sized excess heat.

“The encouraging thing about the Mizuno technology,” says Frank Acland, “is that he’s written a paper giving the instructions, saying exactly how he did it, and encouraging others to follow suit. And from what I’ve seen, there are numerous people who are interested in doing this or already are doing this.”

“Actually I read on your website Cold Fusion Now! that Mizuno said that he’s given reactors to 12 different groups to test out, and I’m very interested to learn what they report. I hope it won’t be too long. Mizuno himself said the he was going to reveal data, maybe at the ICCF-22 conference.”

“I also saw there was a group in Estonia called Deneum and they put a video out showing themselves doing the actual preparation.”

Ruby spoke up about the possible toxicity of nickel dust and that preparation of the mesh should be done in a glove box for maximum safety.

“Mizuno sad that nickel powder is very toxic, responded Frank, “I’m sure it’s important to take every safety recommendation.”

“Also, the Martin Fleischmann Memorial Project’s Alan Goldwater has published a live document talking about his preparations, I’m not sure what stage he’s at yet, but I’m encouraged!”

Energy 2.0 Society prepares for breakthrough

“The Energy2.0 Society is a small group of people mostly from Iowa, though one of our members is from Washington State. We formed in 2015 because we all felt like LENR was an important technology, and we all wanted to encourage more people to investigate it and learn more about it.”

“For quite a while, it’s been difficult to get this message out, there’s not really much that one could point to in terms of a third party saying yes, this is real and this works.”

“We’ve had some discussions recently about the development of the Mizuno technology and we’re hopeful that within the not-to-distant future, we’d like to have more meetings and discussions with people outside of the LENR community about what this technology can do, what its potential is, and what the implications are for society in general. But we haven’t had very much to hold up and say ‘look at this!’ We’ve been sort of watching and waiting, along with many other people following this technology. and we’re hoping that maybe in the next year or so, there will be more to talk about.”

“The cold fusion community is a very small community by the size of it, when you compare it to other things that people are interested in like politics, music, sports. I’d say there’s probably maybe 10,000 people around the world who follow it seriously. The solar industry is a huge industry, with many thousands of people working in it; it’s massive compared to cold fusion. But I think at some point, cold fusion will be where solar is right now.”

“Go to E-CatWorld.com and that’s where you can find everything I’ve published over the years, I think its over 3000 posts – it’s been a long time – and I’ve never tired of it yet. Someone’s got to do it!”

“Sometimes it’s a bit of chore, but most of the time it’s a labor of love.”

Listen to Frank Acland creator of E-CatWorld.com on the Cold Fusion Now! podcast with Ruby Carat on our podcast page.

“Any element that reacts with hydrogen appears to support LENR – titanium, nickel, zirconium have all been explored. The big challenge is to find out what it is about those hydrides that is unique and makes it possible to initiate a nuclear reaction.” says Dr. Edmund Storms, a nuclear chemist and LENR researcher. “Rossi found that nickel is important, but there’s a certain lack of understanding of what Rossi did.”

“Any element that reacts with hydrogen appears to support LENR – titanium, nickel, zirconium have all been explored. The big challenge is to find out what it is about those hydrides that is unique and makes it possible to initiate a nuclear reaction.” says Dr. Edmund Storms, a nuclear chemist and LENR researcher. “Rossi found that nickel is important, but there’s a certain lack of understanding of what Rossi did.”

Mats Lewan is a science and technology journalist and author of An Impossible Invention, the true story of an Energy Source that could Change the World, a book detailing the early demonstrations of Andrea Rossi’s Energy Catalyzer. He joins Ruby on the Cold Fusion Now! podcast where he discusses his assessment of the LENR technology challenge.

Mats Lewan is a science and technology journalist and author of An Impossible Invention, the true story of an Energy Source that could Change the World, a book detailing the early demonstrations of Andrea Rossi’s Energy Catalyzer. He joins Ruby on the Cold Fusion Now! podcast where he discusses his assessment of the LENR technology challenge.

Abd ul-Rahman Lomax created the blog

Abd ul-Rahman Lomax created the blog