Modifications to the cold fusion energy reactor designed by Tadahiko Mizuno have dramatically increased excess heat production. Thermal power output of the cell is now able to exceed the air-flow calorimeter’s heat removal capacity of 1 kilowatt.

This is reported in the paper Increased Excess Heat from Palladium Deposited on Nickel [.pdf]. Co-author Jed Rothwell will describe the spectacular results at the 22nd International Conference on Condensed Matter Nuclear Science ICCF-22 this September 2019 in Assisi, Italy.

When the input is 300 Watts heat, thermal power output is estimated to be between 1 – 3 kilowatts. This is based on the fact that Prof. Mizuno heated his room in Sapporo last winter with the cold fusion reactor, and he felt the room’s temperature to be as warm as when using a 3 kilowatt electric heater.

The jump in power occurred after he placed the heater that regulates the reaction at a new location inside of the cell, as well as new and different applications of pressure to the reactor.

But he also changed the way he made the active cathode material.

Nickel-mesh physically rubbed with palladium rod provides the reactant

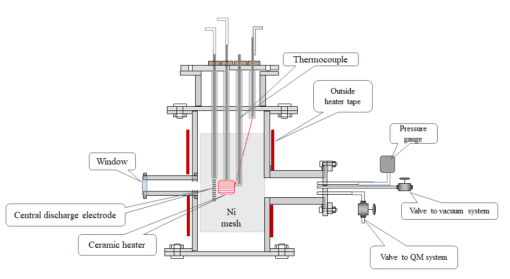

Previously, to produce active nickel-mesh cathodes Prof. Mizuno, lead researcher at Hydrogen Engineering Application & Development HEAD, had been using glow discharge to “erode the center of the palladium electrode and sputter palladium on the nickel mesh”. This method could reliably generate 232 Watts excess heat with 248 Watts input, but it took months of applying the discharge to complete an active cathode. He needed a new method of applying palladium to the nickel-mesh.

Electroless deposition gave good results, but the chemical solution was expensive. So, Prof. Mizuno started physical rubbing a palladium rod on the nickel-mesh to save money.

Three separate nickel mesh pieces are prepared by rubbing “vigorously” with a palladium rod. A careful WARNING is included: the procedure should take place in a glove box or appropriate facility as the fine particles of nickel dust are toxic and pose a health danger. Only those “skilled in the art” should attempt reproduction.

The three mesh are carefully weighed during rubbing until 15-20 milligrams of palladium is deposited on each mesh. Then, the three mesh are stacked and rolled up. Inserted into the steel cylindrical reactor, they are unrolled inside, and spring-out against the cylinder walls.

This new method of cathode preparation is faster than glow discharge, however, first attempts to activate the mesh saw excess power results dropping to 12 Watts, about 12% excess heat, a marginal result.

Heat regulates the reaction

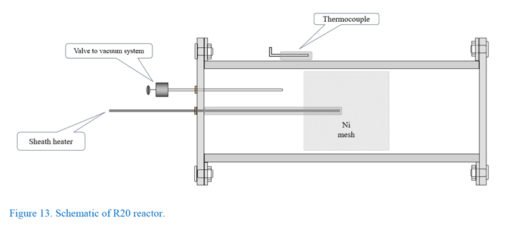

Then, in this last year, Prof. Mizuno changed the design. A sheath heater was installed inside the center of the cylindrical reactor R20.

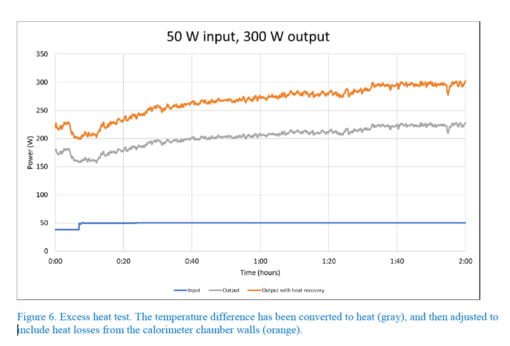

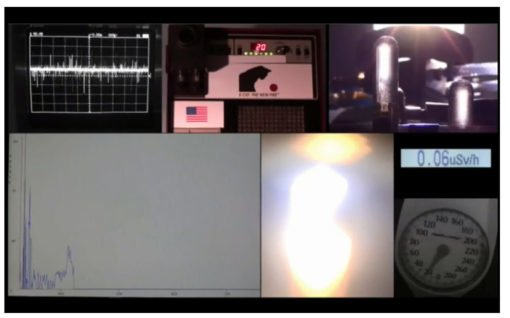

That design change, along with “changes in the methods and pressures”, has “apparently enhanced the reaction, producing the results shown in Fig. 6.”

Jed Rothwell was surprised at the result of moving the heater. He says, “I might have moved it inside just to reduce overall input power, but I had no idea that might increase output.”

Observations on this system has led to some important conclusions.

“First, the excess heat should be an exponential function of absolute temperature,” says Mizuno. “Second, the deuterium concentration in nickel affects the amount of excess heat. Third, the influence of deuterium pressure is small. Also, excessive heat generation requires treatment of the nickel surface. Also, there is a need for dissimilar metal layers. That’s all.”

The R20 is described as the “latest and most effective reactor”. After two hours of operation, it provides a stable ~250 Watts thermal excess power output when the input is a 50 Watt heater, and power generation can continue indefinitely.

However, an input of 300 Watts thermal will produce heat overwhelming the lab’s air-flow calorimeter heat removal capacity. There is an effort to test the R20 reactor in a bigger calorimeter in time to report definitive power output levels at ICCF-22 in September.

Air-flow calorimeter withstands scrutiny

The air flow calorimetry Prof. Mizuno used to measure the heat from the R20 has not changed since the report last year. Calorimeter specifications are described in detail in the previous paper Excess Heat from Palladium Deposited on Nickel [.pdf], which was presented at the ICCF-21 conference. Jed Rothwell, who has worked with Mizuno for over 30 years, invited the CMNS community to help find weak spots, and he has investigated every critique. So far, the calorimetry appears tight.

“Jed’s contribution is huge,” says Prof. Mizuno. “He looked at and analyzed my experimental results in detail, and gave me appropriate advice. He also corrected my dissertation, corrected my analysis errors and corrected sentences. I think Jed is a collaborator.”

Tadahiko Mizuno has shared specific details of these successful experiments in his papers and he is encouraging those “skilled in the art” – and with the proper equipment and protection from toxic nickel dust – to replicate the results. He promises to help replicators, too.

Jed Rothwell has heard from several people planning or starting replications. “Some of them seem to be trying new approaches,” he says. “I am following Dennis Cravens and one other closely. I think they are sticking to the protocol, except that one of the reactors is considerably smaller, so the mesh is only 2″ wide. I hope that has no effect on the results. We’ll see.”

Dr. Dennis Cravens, LENR researcher from New Mexico, is one of those who plans to replicate the active nickel-mesh cathode material process, though he’ll use a different calorimeter.

“Yes, I will be trying a replication in a general way,” he says. “But I have no real support in that effort so it may take some time. I have built an air-flow system using controlled temperature intake. But I have never been comfortable with air-flow systems after using one for checks of molten salt systems. They provide many “targets” for others to “throw darts at” and the questions and “advice” never ends. I am presently assembling a 1 meter long Seebeck for a future attempt.”

Hope is regulated with reality, and Jed Rothwell sums up the feeling of someone who has seen great news come and go, without a technology materializing.

“Once again, cold fusion barely survived. If this cannot be replicated, it may not survive. I do not know of any other approaches that could be widely replicated,” he says. “Without widespread replication, the field will surely die.”

“I hope this can be replicated.”

Says Prof. Mizuno, “I think the most important thing is to know how to generate the excess heat. In addition, it is important that there is a control factor.”

Earthquake almost ended research

Less than one year ago, Tadahiko Mizuno almost quit research after 29 years when a damaging earthquake hit the lab, destroying sensitive equipment.

“The earthquake in the early morning of September 6 was awful”, recalls Tadahiko Mizuno. “The damage was severe; the central part of the SEM is not usually fixed in order to not sway around from earthquakes. This caused a disaster, and the central electron tube hit the surrounding stand and broke. Repair cost is a lot of money. Other than that, machinery was broken. I was unable to work for several months.”

Dennis Cravens started a GoFundMe page and brought the CMNS community together to fundraise just enough cash to clean-up a bit, and continue operations.

“It was an outpouring of help by many in the field,” says Dr. Cravens. “We all have had set backs and often feel alone, alienated, ridiculed and sometimes think of giving up. If we can help each other, we just may have a chance to change the world in a good way.”

As a thank-you, Prof. Mizuno gave small reactor to the community, though not the new nickel-mesh version. Sindre Zeiner-Gundersen, who has been getting his PhD while working with Drs. Leif Holmlid and Sveinn Ólafsson on ultra-dense hydrogen, is now in preparation to test the reactor.

Says Zeiner-Gundersen, “Mizuno is one of the leading scientists in this area and brings great research, results and provides data to the field. He is a true pioneer. The reactor I have is a closed system and should produce excess heat just by applying deuterium and heat to the materials inside. ”

“I’m finishing the last programming on calorimetry and construction of the calorimetry system now, so I will be testing this fall.”

Of course, the small funding from the CMNS community has ran out this past February and Mizuno says, “Now I am testing with debt. The amount is 30 million yen. If this remains the case, I have to leave the company in a couple of months.”

But if replications confirm the kilowatt effect, funding won’t be a problem, and Prof. Mizuno isn’t waiting around. He’s put reactors that he calls HIKOBOSHI in the hands of users, for other labs to independently test.

“I rented and sold 12 CF furnaces to Japan and overseas. They are collecting data and having a lot of data, I am going to announce the data.”

“I have named these reactors as HIKOBOSHI. This means the star Altair. I also like that I feel the meaning in Japanese, which is to “flood the lights”. Hiko is also the last kanji notation of my name.”

Had Tadahiko Mizuno not continued research, this breakthrough bump in kilowatt power would have been unrealized. Now when the world needs a zero-carbon option, the HIKOBOSHI reactor is a step closer to fulfilling that mission.

Dennis Cravens says, “You are guided by your experience and your gut and I only hope that others follow their dreams and come to a greater understanding of the process and possibly, just possibly, find the key to a reliable working system. “

“Any element that reacts with hydrogen appears to support LENR – titanium, nickel, zirconium have all been explored. The big challenge is to find out what it is about those hydrides that is unique and makes it possible to initiate a nuclear reaction.” says Dr. Edmund Storms, a nuclear chemist and LENR researcher. “Rossi found that nickel is important, but there’s a certain lack of understanding of what Rossi did.”

“Any element that reacts with hydrogen appears to support LENR – titanium, nickel, zirconium have all been explored. The big challenge is to find out what it is about those hydrides that is unique and makes it possible to initiate a nuclear reaction.” says Dr. Edmund Storms, a nuclear chemist and LENR researcher. “Rossi found that nickel is important, but there’s a certain lack of understanding of what Rossi did.”

Robert Godes, the President and Chief Technical Officer of

Robert Godes, the President and Chief Technical Officer of